Enviado por

felipeanderson26

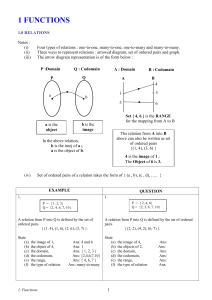

2012 Zang

Materials and Design 36 (2012) 75–80 Contents lists available at SciVerse ScienceDirect Materials and Design journal homepage: www.elsevier.com/locate/matdes Hybrid composite laminates reinforced with glass/carbon woven fabrics for lightweight load bearing structures Jin Zhang, Khunlavit Chaisombat, Shuai He, Chun H. Wang ⇑ Sir Lawrence Wackett Aerospace Research Centre, School of Aerospace, Mechanical and Manufacturing Engineering, RMIT University, Melbourne, VIC 3083, Australia a r t i c l e i n f o Article history: Received 6 September 2011 Accepted 3 November 2011 Available online 12 November 2011 Keywords: A. Composites B. Laminates H. Selection for material properties a b s t r a c t Light-weight structure utilising novel design and advanced materials is one of the keys to improving the fuel efficiency and reducing the environmental burden of automotive vehicles. To ensure the low cost of applying fibre-reinforced materials in automotive vehicles, it is proposed to selectively incorporate carbon fibres to enhance glass fibre composites along main loading path. This paper investigates the influences of stacking sequence of on the strength of hybrid composites comprising materials with differing stiffness and strength. Hybrid composite laminates were manufactured using varying ratio of glass woven fabric and carbon woven fabric in an epoxy matrix. Static tests including tension, compression and three-point-bending were carried out to composite coupons containing various ratios of carbon fibres to glass fibres. The results show that hybrid composite laminates with 50% carbon fibre reinforcement provide the best flexural properties when the carbon layers are at the exterior, while the alternating carbon/glass lay-up provides the highest compressive strength. The tensile strength is insensitive to the stacking sequence. Analytical solutions are also developed and are shown to provide good correlation with the experimental data, which allow the optimisation of stacking sequence of hybrid composites to achieve the maximum strength. Ó 2011 Elsevier Ltd. All rights reserved. 1. Introduction The shortage of fossil fuel supply and the new imperative of environmental sustainability to combat global warming have exerted tremendous pressure on transforming the current materials design and manufacturing technologies for human transportation (air, land and sea). Lightweight is rapidly becoming a necessity for structures, as a result of its less energy consumption from the vehicles which take into account of this critical issue. While plastic and composite materials are used in automobiles today, they constitute only approximately 7.5% of total vehicle mass and the applications are generally not for the primary vehicle structure [1]. Important reasons for the growing adoption of polymer matrix composites [2] are the reduced weight (30–40% lighter than steel parts of equal strength), part consolidation opportunities, design flexibility, reduced tooling cost, better damage and corrosion resistance, material anisotropy and improved internal damping, etc. Although the great advantages of polymer matrix composites have been recognised by automotive industry, there exist a number of critical challenges before their wide use in primary automotive structures. Concerns about high material costs, slow production rates and recyclability and the auto-industry’s lack of experience ⇑ Corresponding author. Tel.: +61 3 99256115; fax: +61 3 9925 6108. E-mail address: [email protected] (C.H. Wang). 0261-3069/$ - see front matter Ó 2011 Elsevier Ltd. All rights reserved. doi:10.1016/j.matdes.2011.11.006 with composite materials, are the main problems automakers are facing currently [1,3,4]. The most popular reinforcements for polymer matrix composites are carbon and glass fibres. It has been estimated that the use of glass fibre reinforced polymer matrix (GFRP) composites as structural components could yield a 20–35% reduction in vehicle weight; more significantly, the use of carbon fibre reinforced polymer matrix (CFRP) composites could yield a 40– 60% weight reduction [5]. While fibreglass composites have been increasingly used to replace steel in automotive industry [6,7], the adoption rate for carbon fibre composites which are much lighter, stronger and stiffer than glass fibre composites, remains low. The main reason is the high cost of carbon fibres; that is also the reason why CFRP composites are only popular in concept and luxury cars and aerospace vehicles. Different from the aerospace sector, where additional payload capacity and engine efficiency are the paramount issues, the high-volume production of automotive industry results in the most important consideration of being cost-effective that overwrites any technical concerns [8]. Cost reduction continuously to be the number one challenge facing automobile manufacturers while fuel economy and technology transformation are becoming more important [9]. To further reduce vehicle weight without excessive cost increase, one technique is to incorporate carbon fibre reinforcement into glass fibre composites and innovatively design by selectively reinforcing along the main load path [10–12]. Hybrid composites J. Zhang et al. / Materials and Design 36 (2012) 75–80 2. Experimental procedure Colan™ E-glass plain weave fabric and Sigmatex™ carbon 2/2 twill weave fabric (T300, 3 K Tow, 199 GSM) were used to reinforce West system epoxy 105 cured with slow hardener 206. Wet lay-up was applied to fabricate laminates with five different lay-up schemes: [C]8, [C2G2]s, [CG3]s, [CGCG]s and [G]8, where C and G denote carbon fibre and glass fibre respectively. The composite laminates were cured at ambient temperature for 24 h before cut into specimens for mechanical tests. The overall fibre weight fraction of the composites was approximately 45%. The ASTM D3039-76 [21] and ASTM D 790 [22] standards were used for tension and threepoint-bending tests; the compression tests were performed using a NASA short block compression fixture. The thickness of the cured composite laminates was between 2.5 mm and 3.5 mm. The specimen dimensions were 250 mm 25 mm for tensile and were 100 mm 25 mm for flexural tests. The compression specimens were grinded to ensure perfectly horizontally parallel top and bottom edges, with the dimension of 52 mm 25 mm. The optical micrographs were taken from a Leica EZ4D and a DP 71 optical microscope. 3. Results and discussion 3.1. Hybrid composites under tensile and compressive loading With the variation of composition, the density for five types of composites varied from 1.508 g/cm3 for the plain glass fibre composite [G]8 to 1.460 g/cm3, 1.327 g/cm3, 1.316 g/cm3 and 1.237 g/cm3 for the [CG3]s, [C2G2]s, [CGCG]s and [C]8 composites, respectively. The addition of carbon fibre reinforcement reduced the density of the composites. The tensile and compressive stress–strain curves 500 Tensile Stress (MPa) are composed of more than one type of reinforcement and they can be classified into interply or laminated hybrid, intraply or tow -by-tow hybrid, intimately mixed hybrid, and other types of mixtures. Some of the influential factors that affect the composite mechanical performance from the reinforcement include the length of fibre, fibre orientation, fibre shape and fibre material [13,14]. Since the mechanical properties of glass and carbon fibres, and the interfacial properties between reinforcement and matrix differ greatly, the hybridisation effects would vary too for the hybrid composites [15–17]. A comprehensive review on the mechanical properties of hybrid fibre reinforced plastics especially on glass/carbon hybrid composites showed that the longitudinal tensile moduli are generally in good agreement with the rule of mixture, which is due to the strain compatibility through the thickness of a hybrid material [18]. The review also showed that the shape of the stress–strain curves for hybrid composites varies with the different type of fibres and resins used, the overall fibre fraction and the orientation of the reinforcement in the material. Positive hybrid effect was observed in flexure tests of specimens with high glass versus carbon fibre ratio [19]; however, the compression and fracture energy of glass/carbon epoxy matrix composites exhibited negative hybrid effect [18]. In a recent study, the tensile and compressive loading cases on hybrid glass/carbon fabric composites have been investigated and the main observation of this work is that by placing glass fabric layers in the exterior and carbon fabric layers in the interior, higher tensile strength and ultimate tensile strain were obtained [20]. In the present study, E-glass and carbon fibre woven fabrics with epoxy resin matrix have been used for fabricating hybrid laminates. Different glass/carbon ratios and stacking sequences were investigated against the tensile, compressive and flexural responses of hybrid composite laminates. 1: 2: 3: 4: 5: a 1 400 300 2 [C]8 [C2G2]s [CG3]s [C/G/C/G]s [G]8 4 5 3 200 100 0 0.0 0.5 1.0 1.5 2.0 Tensile Strain (%) 1: 2: 3: 4: 5: 500 Compressive Stress (MPa) 76 b 400 300 1 200 2 4 3 5 100 0 0.0 [C]8 [C2G2]s [CG3]s [C/G/C/G]s [G]8 0.5 1.0 1.5 2.0 2.5 3.0 3.5 Compressive Strain (%) Fig. 1. Tensile and compressive stress–strain curves for different composite laminates. for all five types of composite laminates are shown in Fig. 1 and the calculated mechanical property data are included in Table 1. As expected, the [C]8 composite had the highest tensile and compressive strength and the [G]8 composite had the lowest tensile and compressive strength, where the average tensile and compressive strength of plain glass fibre composites account for almost 50% of the plain carbon fibre composites for both tension and compression loading cases. The compressive strength of [C]8 was 38% lower than its tensile strength and the compressive strength of [G]8 was 42% lower than its tensile strength. At the same glass/carbon fibre ratio, [C2G2]s and [C/G/C/G]s showed similar tensile strength; however, higher compressive strength and strain were found for the [C/G/C/G]s than the [C2G2]s. With the addition of 25% of carbon fibres in the exterior layers, [CG3]s exhibited only slight improvement in both tensile and compressive strength than plain glass composite [G]8. The compressive strain resulted from the alternating lay-up scheme ([CGCG]s) showed the highest value above all other composites. The enhanced compression strength for the alternating stacking sequence may be caused by the bridging effect of the carbon fibre layer between the failed glass fibre layers. Kretsis has concluded that in hybrid composites, the weakest low-elongation fibres break first to form cracks that are ‘bridged’ by the surrounding high-elongation composite, thus allowing the stronger low-elongation fibres to reach their ultimate strength [18]. A similar explanation has also been given by Manders who pointed out that the hybrid effect arises from a failure to realise the full potential strength of the fibres in all-carbon fibre composites, rather than from an enhancement of their strength in the hybrids [23]. 77 J. Zhang et al. / Materials and Design 36 (2012) 75–80 Table 1 Mechanical properties of composite laminates under tensile and compressive loading. Lay-up scheme Tensile strength (MPa) Ultimate tensile strain (%) Young’s modulus for tension (GPa) Compression strength (MPa) Ultimate compressive strain (%) Young’s modulus for compression (GPa) [C]8 [C2G2]s [CG3]s [C/G/C/G]s [G]8 420 260 206 263 200 1.07 1.18 1.41 1.40 1.87 38.39 22.04 18.09 22.27 11.01 260 171 189 217 117 3.06 2.63 3.01 3.13 2.76 10.97 7.40 7.72 8.22 5.14 (±0.13) (±0.06) (±0.14) (±0.38) (±0.29) (±2.43) (±1.50) (±0.54) (±0.84) (±2.11) The linear rule of mixture (ROM) was used for calculating the tensile and compressive strength. Denoting the carbon fibre ratio of all fibre reinforcement is a, the Young’s modulus can be expressed using the simple rule of mixtures as: E ¼ aEC þ ð1 aÞEG ð1Þ where E denotes the modulus of hybrid composite, EC denotes the modulus of carbon fibre composite and EG denotes the modulus of glass fibre composite. So the stress (r) of the hybrid composite can be expressed as r ¼ ðEC tC þ EG tG Þec =ðtC þ tG Þ ð2Þ Assuming a equals to the percentage of the thickness of carbon layers (tC) in the whole laminate (tC + tG) and the composite fails when the elongation of laminates reaches ec. However, in real case, the glass fibres can still carry load until the ultimate strain of glass fibre composite is reached. Therefore the maximum stress of hybrid composites is rmax ¼ max ½ec ðEC tC þ EG tG Þ=ðtC þ tG Þ; EG tG eG =ðtC þ tG Þ ð3Þ As it can be seen from Fig. 2, the tensile strength results agreed well with analytical results; however, the compressive strength exhibited a negative hybridisation effect, where the hybridisation effect is shown by the deviation from the ROM behaviour. Stevanovic et al. found similar results when they investigated the tensile properties of unidirectional carbon fibric /non wovon glass mat/ polyester resin hybrid composite laminates. The tensile moduli of their tested composites agree with values calculated by the ROM [19]. The ROM could not demonstrate the difference in the compressive strength of [C2G2]s and [CGCG]s composites, due to the same carbon/glass fibre ratio. Maximum Stress (MPa) 500 σT-experimental (±12) (±38) (±33) (±42) (±8) eðzÞ ¼ jz ð4Þ where z denotes the coordinate along the thickness direction (Fig. 4). Different fibre reinforced composite plies can exhibit significantly different failure strains. For instance, unidirectional glass/ polyester laminae can reach an axial failure strain of approximately 500 1: 2: 3: 4: 5: 1 400 2 4 300 3 [C]8 [C2G2]s [CG3]s [C/G/C/G]s [G]8 5 200 100 0 0.0 σC-experimental 0.5 1.0 1.5 2.0 2.5 3.0 Flexural Strain (%) σC-analytical 300 (±0.18) (±0.83) (±1.59) (±1.75) (±0.17) The flexural stress–strain curves for all five types of composite laminates are shown in Fig. 3 and the calculated mechanical property data are included in Table 2. As expected, the [C]8 composite had the highest flexural strength and lowest flexural strain, which is the opposite case to the [G]8 composite. Placing two carbon layers at the exterior effectively increased the flexural strength, as shown in the stress–strain curve for the [C2G2]s composite. The flexural strength of the [C2G2]s was 406 MPa, accounting for 89% of the plain carbon fibre laminate [C]8. By placing the high stiffness carbon fibre away from the neutral axis and the low stiffness glass fibre at the neutral axis, the flexural modulus is enhanced significantly, which is also proved by other researchers work [24]. Based on the plane section assumption, the strain distribution in the laminate can be expressed in terms of the curvature j, with the origin of the coordinate being at the mid plane of the composite laminate, σT-analytical 400 (±0.21) (±0.30) (±0.20) (±0.21) (±0.20) 3.2. Hybrid composites under flexural loading Flexural Stress (MPa) (±57) (±7) (±9) (±11) (±3) Fig. 3. Flexural stress–strain curves for different composite laminates. 200 [CGCG]s [C2G2]s 100 0 0 20 40 60 Table 2 Mechanical properties of composite laminates under flexural loading. 80 100 Carbon Fibre Ratio (%) Fig. 2. Tensile and compressive strength of composite laminates affected by the carbon fibre ratios in the reinforcement (both experimental and analytical results). rT is the tensile strength and rC is the compressive strength. Lay-up scheme Flexural strength (MPa) Ultimate flexural strain (%) Flexural modulus (GPa) [C]8 [C2G2]s [CG3]s [C/G/C/G]s [G]8 455 406 339 348 218 1.69 1.68 1.78 1.81 3.00 29.03 27.31 21.98 22.47 11.12 (±35) (±17) (±15) (±9) (±9) (±0.04) (±0.04) (±0.05) (±0.08) (±0.10) (±2.09) (±1.19) (±0.91) (±0.70) (±0.46) 78 J. Zhang et al. / Materials and Design 36 (2012) 75–80 jmax ¼ min ec ðzi Þ et ðzi Þ ; zi zi ; i ¼ 1; 2; 3 . . . N ð5Þ where ec(zi) denotes the strain of the ith ply under compression and et(zi) denotes the stress of the ith ply under tension. It is clear that maximum deformation (curvature) occurs when plies with the highest failure strain are placed close to the surface, far removed from the neutral axis. The bending moment of a beam with rectangular section is given by, Fig. 4. The rectangular beam under bending. M¼ Z t=2 rx ðzÞzBdz ¼ j t=2 Maximum Stress (MPa) [C2G2]s 400 300 [CGCG]s M¼ 200 σF-experimental σF-analytical 100 0 0 20 t=2 zEðzÞBdz ð6Þ t=2 where t is the thickness of the beam, B is the width of the structure, rx(z) is the stress either in compression or tension and E(z) denotes the Young’s modulus of the material at coordinate z. It can be seen from Eq. (6) that the maximum bending moment of a hybrid laminate depends on through-thickness distribution of the strain-tofailure and lamina stiffness. Considering a symmetric laminate with eight plies, the moment is 600 500 Z 40 60 80 100 Carbon Fibre Ratio (%) Fig. 5. Flexural strength of composite laminates affected by the carbon fibre ratios in the reinforcement (both experimental and analytical results). N BX ðt2 t2i1 Þ½EðiÞT þ EðiÞC j 2 i¼1 i where ti denotes the locations of the ith ply of a laminate containing a total of 2N plies in a symmetric lay-up. Because for a rectangular section, the maximum flexural stress can be written as rmax ¼ M=S ¼ M=ðBt2 =6Þ ¼ 6M=Bt2 a N X t2i t2i1 ½EðiÞT þ EðiÞC j ð9Þ i¼1 If 50% of the reinforcement is carbon fibre, the maximum flexural stress can be obtained when two carbon fibre composite layers are located at the exterior of the laminate. Both the experimental and analytical flexural strength data are shown in Fig. 5. The analytical solutions were able to simulate the experimental trend influenced by hybrid composition and stacking sequence; however, their calculated results were higher than the experimental data due to the shear stresses presented in the specimens which b d ð8Þ where S is the elastic section modulus. The maximum flexural stress can be determined as rmax ¼ ð3=t2 Þ 2%, the strain-to-failure for type I carbon/epoxy unidirectional laminae is approximately 0.5% [25], and the natural fibre/epoxy composite strain can reach 5.2% when jute is used as reinforcement [26]. So for a hybrid composite laminate under pure bending load, the maximum bending moment it can carry corresponds to the load when a certain ply in the laminate reaches its failure strain. Due to the potentially very large difference in failure strains of different types of composite materials, critical location may not always be the surface ply. The maximum curvature at failure of the laminate is ð7Þ c e Fig. 6. Optical micrographs of failed composite laminates under tensile loading. (a) [C]8, (b) [C2G2]s, (c) [CG3]s, (d) [CGCG]s and (e) [G]8. (b) and (c) show the edge views of failed tensile specimens and the rest show the facture surfaces. 79 J. Zhang et al. / Materials and Design 36 (2012) 75–80 a b d c e Fig. 7. Optical micrographs of failed composite laminates under compressive loading. (a) [C]8, (b) [C2G2]s, (c) [CG3]s, (d) [CGCG]s and (e) [G]8. a b d c e Fig. 8. Optical micrographs of failed composite laminates under flexural loading. (a) [C]8, (b) [C2G2]s, (c) [CG3]s, (d) [CGCG]s and (e) [G]8. caused additional displacements and led to reduced modulus. For the low span-to-depth ratios and high modulus materials, these shear stresses are more significant [18,19]. 3.3. Failure modes of hybrid composite laminates The failed composite specimens were investigated under optical microscopes. Fig. 5a, d and e presents the tensile fracture surface of the [C]8, [CGCG]s and [G]8 composites. The fibre pull-outs of the plain glass fibre composite were more significant than the plain carbon fibre composite [C]8 and the alternating carbon/glass fibre laid-up composites [CGCG]s. In comparison, the composites with one or two carbon fibre layers at the exterior did not break into two halves, with glass fibres bridging the ruptured carbon surface layers (Fig. 6b and c shows the edge view of the tensile specimens). The optical micrographs in Fig. 7 display the compression failure of different types of composites. It can be seen that the carbon fibre layers failed with a transverse catastrophic mode, wherever the glass fibre layer failed with the typical kinking–slitting mode. By applying the alternating lay-up scheme, the compression failure was effectively suppressed. Fig. 8 presents the cross-sections of the failed flexural specimens along the central line of span. The plain carbon fibre composite [C]8 exhibited brittle failure, where the specimen broke through all layers with abundant carbon fibre rupture. The other four types of composite laminates showed more matrix fracture other than reinforcement failure, in comparison with the compression failure modes. With the hybridisation of the reinforcement, the brittle and catastrophic failure mode of the all carbon fibre composite is avoided. It can be concluded that improvement in the balance of stiffness and toughness in composite laminates can be realised through hybridisation [24,27]. 4. Conclusion Five types of composite laminates, i.e. [C]8, [C2G2]s, [CG3]s, [CGCG]s and [G]8 composites, were investigated under static load- 80 J. Zhang et al. / Materials and Design 36 (2012) 75–80 ing under tension, compression and three-point-bending. To effectively improve the tensile, compressive and flexural strength of the plain glass fibre composite, glass/carbon (50:50) fibre reinforcement was used either by placing the carbon layers at the exterior or by placing different fibre types alternatively. With the same hybrid composition, the stacking sequence did not show noticeable influence on the tensile properties but affected the flexural and compressive properties significantly. The current composite system exhibited more matrix failure under flexural loading and more reinforcement failure under compressive loading. Acknowledgement This work was supported by the ‘‘Lightweight Modular Vehicle Platform’’ project of Australian Cooperative Research Centre for Advanced Automotive Technology (Auto CRC). References [1] Cramer DR, Taggart DF. Design and manufacture of an affordable advancedcomposite automotive body structure. In: The 19th international battery, hybrid and fuel cell electric vehicle symposium & exhibition; 2002. [2] Plastics in automotive markets technology roadmap: a new vision for the road ahead. The plastic division of the American Chemistry Council (ACC); 2009. [3] Beardmore P, Johnson CF. The potential for composites in structural automotive applications. Compos Sci Technol 1986;26:251–81. [4] Thilagavathi G, Pradeep E, Kannaian T, Sasikala L. Development of natural fiber nonwovens for application as car interiors for noise control. J Ind Text 2010;39:267–78. [5] Das S. The cost of automotive polymer composites: a review and assessment of DOE’s lightweight materials composites research. Oak Ridge National Laboratory; 2001. p. 1. [6] Al-Qureshi HA. Automobile leaf springs from composite materials. J Mater Process Technol 2001;118:58–61. [7] Hosseinzadeh R, Shokrieh MM, Lessard LB. Parametric study of automotive composite bumper beams subjected to low-velocity impacts. Compos Struct 2005;68:419–27. [8] Tucker N, Lindsey K. An introduction to automotive composites. Rapra Technology Limited; 2002. [9] Jacob A. Automotive composites – the road ahead. Reinf Plast 2001;45:28–32. [10] Mahdi E, Hamouda AMS, Sahari BB, Khalid YA. Effect of hybridisation on crushing behaviour of carbon/glass fibre/epoxy circular-cylindrical shells. J Mater Process Technol 2003;132:49–57. [11] Hosur MV, Adbullah M, Jeelani S. Studies on the low-velocity impact response of woven hybrid composites. Compos Struct 2005;67:253–62. [12] Nordin H, Täljsten B. Testing of hybrid FRP composite beams in bending. Composites Part B 2004;35:27–33. [13] Kaw AK. Mechanics of composite materials. 2nd ed. Tampa: CRC Press, Taylor & Francis Group; 2005. [14] Grujicic M, Pandurangan B, Koudela KL, Cheeseman BA. A computational analysis of the ballistic performance of light-weight hybrid composite armors. Appl Surf Sci 2006;253:730–45. [15] Fu SY, Mai YW, Lauke B, Yue CY. Synergistic effect on the fracture toughness of hybrid short glass fiber and short carbon fiber reinforced polypropylene composites. Mater Sci Eng A 2002;323:326–35. [16] Giancapro JW, Papakonstantinou CG, Balagura PN. Flexural response of inorganic hybrid composites with E-glass and carbon fibers. J Eng Mater Technol 2010;132:1–8. [17] Hwang S, Mao C. Failure of delaminated interply hybrid composite plates under compression. Compos Sci Technol 2001;61:1513–27. [18] Kretsis G. A review of the tensile, compressive, flexural and shear properties of hybrid fibre-reinforced plastics. Composites 1987;18:13–23. [19] Stevanovic M, Stecenko T. Mechanical behaviour of carbon and glass hybrid fibre reinforced polyester composites. J Mater Sci 1992;27:941–6. [20] Pandya KS, Veerraju C, Naik NK. Hybrid composites made of carbon and glass woven fabrics under quasi-static loading. Mater Des 2011;32:4094–9. [21] ASTM International. Standard test methods for tensile properties of fiber-resin composites. ASTM D 3039-76. Philadelphia (PA): Annual book of ASTM standards; 1989. [22] ASTM International. Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. ASTM D 790-84. West Conshohockon (PA): Annual book of ASTM Standards; 1990. [23] Manders PW. PhD thesis. The strength of mixed fibre composites. University of Surrey, 1979. [24] Naik NK, Ramasimha R, Arya H, Prabhu SV, ShamaRao N. Impact response and damage tolerance characteristics of glass–carbon/epoxy hybrid composite plates. Composites Part B 2001;32(7):565–74. [25] Hull D, Clyne TW. An introduction to composite materials. In: Clark DR, Suresh S, Ward FRS IM, editors. 2nd ed. Cambridge University Press; 1996. [26] Hakim S, Sultan Aj. Energy systems and crushing behaviour of fiber reinforced composite materials. World Acad Sci Eng Technol 2011;74:280–6. [27] Manders PW, Bader MG. The strength of hybrid glass/carbon fibre composites. J Mater Sci 1981;16(8):2233–45.